Hizmetlerimiz

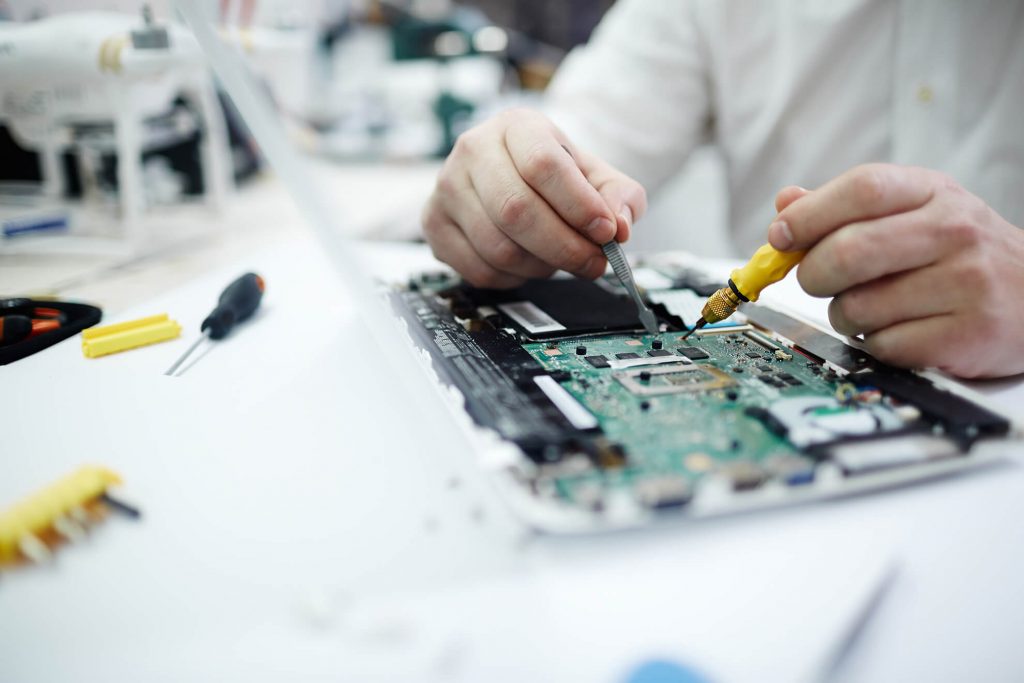

Üretim

Üretim Faaliyetleri prototip aşmasına kadar şirketimiz bünyesindeki atölye ve laboratuarlarda gerçekleştirilmektedir.

Mekanik atölye bünyesindeki, 4 eksenli cnc torna, matkap vb. talaşlı imalat tezgahları, Sac kesme kıvırma Iistasyonları, kaynak istasyonu vb. ekipmanlar kullanılmaktadır.

Tasarım

Tasarım faaliyetleri, mühendislik ekibinin ana toplantısı ile başlar, üründen beklenen talepler, pazardaki ürünün rakiplerinin teknik özellikleri, ve tasarım çalışmaları yürütülecek konular belirlenir.

Kurumsal hafıza’da yer alan, geçmişte tamamlanmış projelerden alınabilecek ara çıktılar, ve kurumsal hafızaya neler kazandırılabileceği üzerinde beyin fırtınası yürütülür.

Fonksiyon & Çevre Koşulları Testleri

Ürünlerimiz için, elektronik yada mekanik bileşen testleri, konuya özel tasarlayıp ürettiğimiz test düzenekleri aracılığı ile alt bileşenler testleri yapılır.

Elektronik ürünler içindeki regülatörler, anahtarlama elemanları ve giris -çıkışlar ayrı ayrı test edilir ve test dökümentasyonları oluşturulur.